premium ballistic separator machine

Ballistic Classifier for the Separation of Several Fractions of Packaging Waste, Household Waste, Commercial Waste and Mixed Construction Waste

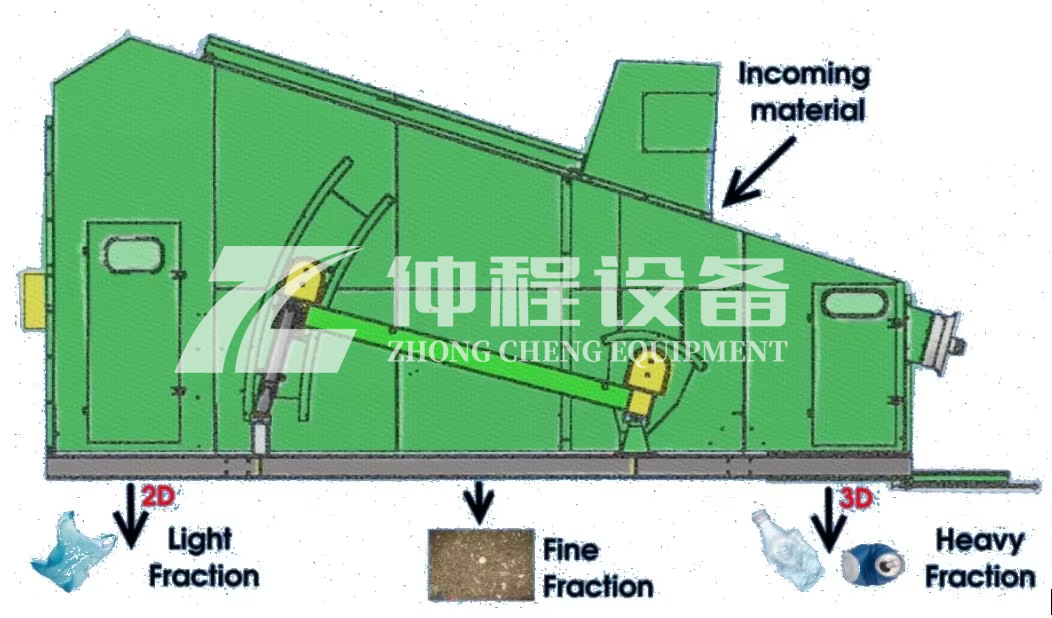

The types of waste that can be screened with the ballistic separator are numerous: lightweight packaging, paper/cardboard, foil and plastic containers, commercial and industrial waste (C&I), municipal solid waste (MSW), waste from construction and demolition (C&D)… Hence, the output flows of a ballistic separator are:

1.heavy and rolling fraction, 3D: flacons and plastic bottles (PET and polyethylene HD), cans, wood, stones…

2.flat and light fraction, 2D: envelopes, trays and plastic film (polyethylene LD), textiles, paper and cardboard…

3.sieved fraction: depending on the size of the holes of the grids on the screening paddles it possible to classify different sizes of underscreen fraction. This fraction, typically not recoverable, has dimensions approximately of 40-50 mm and it contains soil, sand, organic waste and small pieces of recyclables.

Ballistic separators are multifunctional machines which allow to treat various types of waste: from paper and lightweight packaging to construction and demolition as well as municipal solid waste. These machines are capable to divide material stream into three fractions – heavier 3D fractions such as tins or stones, lighter 2D or flat fractions such as paper and film and small-sized fractions which are screened down.

The conveying speed, the ballistic separation and the level of material mixing can be adjusted by modifying the rotational speed. A separation precision of up to 90% can be achieved with the MIND Ballistic Separator.

Equipment has been updated in replacement, please consult the sales staff for specific parameters

PIVOTING FRAME

· With manual tilt adjustment between 0° and 25° for fast adjustment

of sorting quality

EASY MAINTENANCE AND ADJUSTMENT

· Bolt-on screens

· Easy access to all areas of the machinery thanks to maintenance doors

SHAFT QUALITY

· Robust design for sorting dry waste

· Optimum rating of shaft stroke and speed – for maximum throughput

and minimum machine vibrations

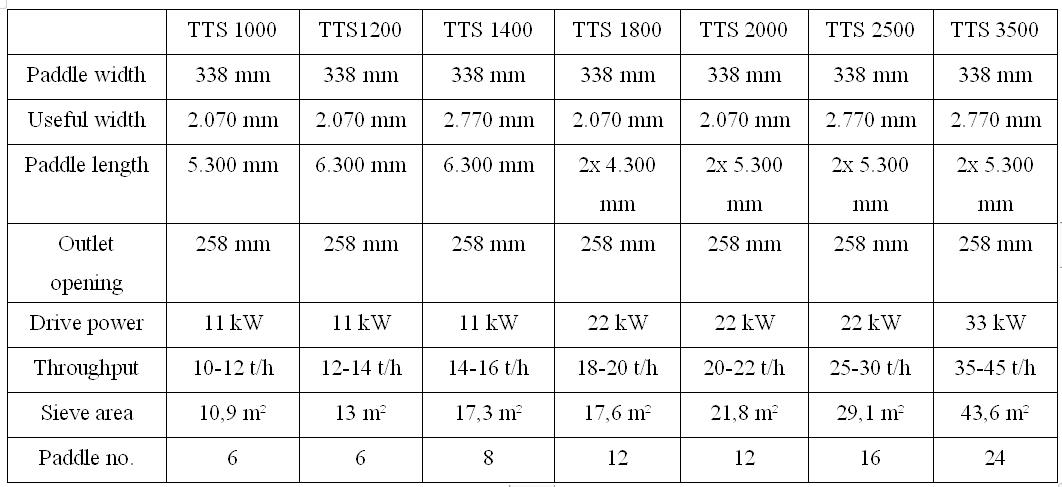

MODEL VARIETY

· A choice of various machine widths and lengths for high-efficiency

sorting processes in line with the required throughputs

STACKING

· A maximum of three ballistic separators can be stacked to increase

the separation quality for different particle size fractions

ADJUSTABLE OUTER SKIN

· For flexible design of the material infeed and plant integration

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-08Five factors influencing the output of a drum screen.The input efficiency and separation efficiency of the drum screen are controlled by the screen hole size, drum screen diameter, rotation speed, baffle type and ...

-

2023-01-12Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...

-

2024-06-20Wind Separator Technology for Lightweight Materials in Urban Solid Wastewind separator, also known as air separation, is a sophisticated and efficient method of sorting that utilizes air as the separating medium.

-

2024-07-09Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...

-

2024-05-18Spring Cone CrusherSpring cone crushers are generally used in the medium and fine crushing links of mine crushing, and are mainly used in the secondary crushing and tertiary crush...