Smart waste management equipment construction and demolition waste sorting recycling plant waste compactor baler machine

Introduction

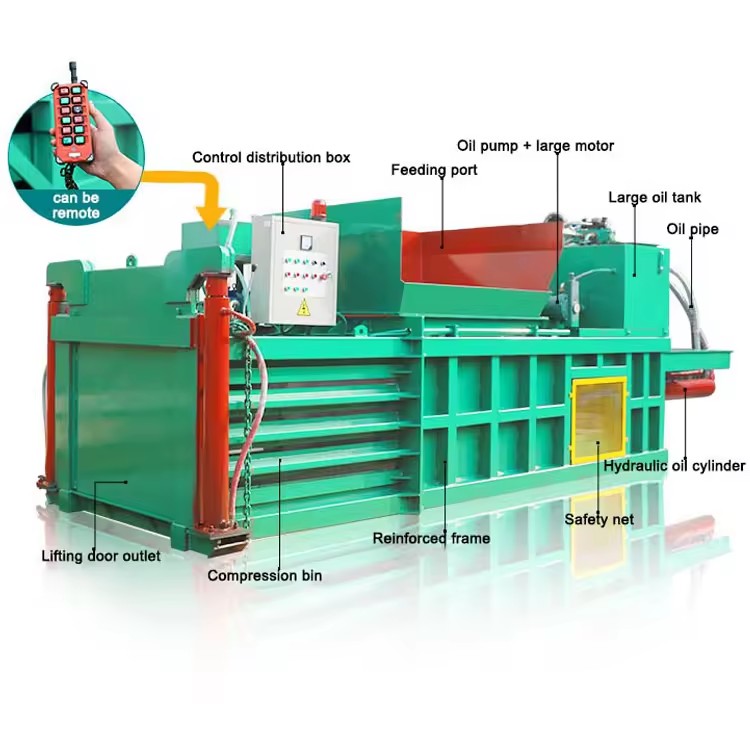

Horizontal hydraulic packaging machine is an efficient and reliable packaging equipment that greatly reduces packaging volume, increases density, and facilitates transportation and storage. It is a powerful helper for the comprehensive utilization and development of biomass energy.

Working Process of waste sorting line/waste sorting recycling plant

5. The plastic will be packed by a baler machine; the stone and soil will be directly sent to outside for landfill or be crushed to make bricks; we can pick out the useful material from the waste, then recycle them.

Application

The horizontal hydraulic packaging machine is mainly suitable for waste plants, crop straw, recycling and processing industries, as well as non-ferrous and ferrous metal smelting industries. The hydraulic packing machine can squeeze various metal scraps, plastic bottles, cans, waste cardboard boxes and other materials into qualified furnace materials in various shapes such as rectangles and squares, which can reduce transportation and smelting costs and improve furnace feeding speed.

Features

4. The use of low-energy hydraulic systems and motors can effectively reduce energy consumption and carbon emissions.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-20A rubber double shaft shredderExamples of Specific Models:GDB Series Biomass Shredder: Although primarily designed for biomass materials, this model can also be configured to handle various ...

-

2023-01-13Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...

-

2024-05-18Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...

-

2024-05-28Garbage screening drum screenTrommel screen is consisting of five parts: drum, frame, hopper, reducer and motor.After the material goes into the drum, it is screened along with the rotation...

-

2024-06-08Solutions for Jaw Crusher ProblemsJaw crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive stren...