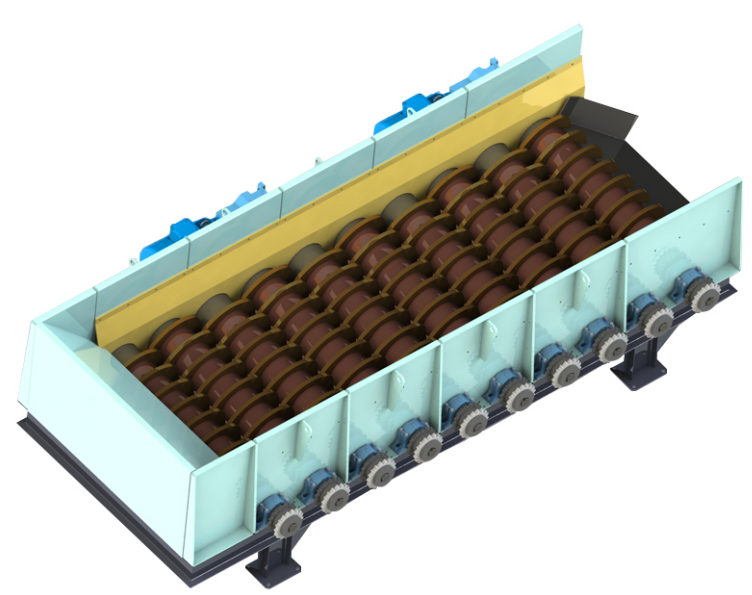

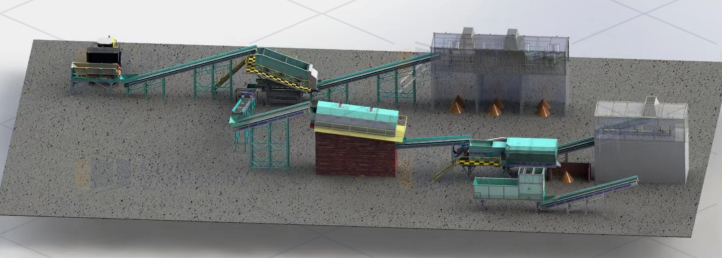

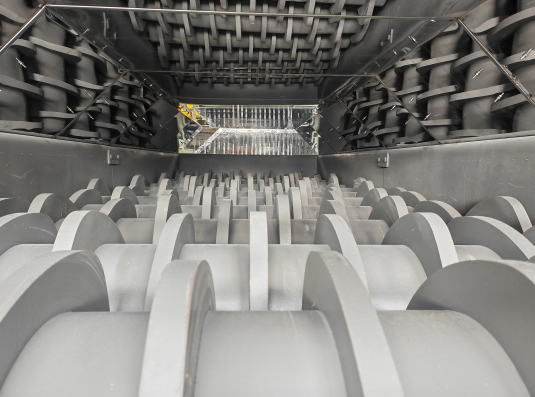

Disc separator

This is the stationary disc screen with a modular structure,

designed for those in need of high performance, compact dimensions,

and limited energy consumption.

Thanks to Dynamic Disc Screening technology, it is able to screen materials faster (1 m/sec),

using less space, and reaching a productivity level of up to 200 t/h. Revenue from the sale

of recycled materials can be increased thanks to the unique characteristics of this system.

The top quality of its components and assembly procedures, exceeding market standards

by far, guarantees maximum reliability and a reduction in maintenance costs.

Maximum efficiency and configuration flexibility

The efficiency of Dynamic Disc Screening technology allows the installation of low power

7.5 kW electric motors for every 4 linear meters of screen.It is built with high quality materials

and can be configured with different disc sizes to screen any type of material: car fluff, SRF

(Solid Recovered Fuel), biomass, compost, construction and demolition debris, incinerator

ash, municipal solid waste, organic waste, paper and cardboard, PET, aggregates, tires and

recycled wood.

There are summary of advantage :

less energy consumption

The efficiency of Dynamic Disc Screening technology enables the use of 7.5 kW electric motors

for outputs of 20 t/h and energy savings of up to 70% compared to traditional screening technologies.

productivity

Hexact is able to screen materials faster (1 m/sec), using less space and reaching

productivity levels up to 200 t/h.

less fixed overhead costs

Thanks to the smaller space required compared to traditional screening technologies,

it enables a reduction in investment costs (space, conveyor belts and steel structures)

by up to 300%.

| FIXED ANGLE | Rated Capacity Residential | Rated Capacity Commercial | Number of Decks | Width | Number of Shafts |

| DS26-12 | Up to 20 tph | Up to 15 tph | 2 | 6’ | 12 |

| DS 36-18 | 20 - 30 tph | 15 - 25 tph | 3 | 6’ | 18 |

| DS 38-18 | Up to 50 tph | 25 - 35 tph | 3 | 8’ | 18 |

| ADJUSTABLE ANGLE | |||||

| DS 26-14 | Up to 25 tph | Up to 20 tph | 2 | 6’ | 14 |

| DS 36-21 | 20 - 40 tph | 20 - 30 tph | 3 | 6’ | 21 |

| DS38-21 | 50 - 60 tph | Up to 40 tph | 3 | 8’ | 21 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-07Zhongcheng Air Drum Separator in MSWAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...

-

2024-08-28Scrap rubber product shredderThe shredder of waste rubber products not only helps to reduce environmental pollution, but also improves the reuse rate of waste rubber, which is one of the im...

-

2024-04-25Recycling Finger ScreensFinger screen is a type of screening equipment used to separate materials based on size. Unlike traditional screens, finger screens consist of a series of paral...

-

2024-05-20Mobile Impact Crusher PlantThe mobile impact crusher plant is a kind of crushing equipment based on a mobile platform. It uses an impact crusher as the host machine and is usually equippe...

-

2024-08-12Wood Pallet ShredderConsiderations When Choosing a Wood Pallet Shredder:Material Type: Different wood types may require specific configurations or materials of construction.Output ...