Drum screen-garbage recycling equipment

Drum screens, also known as trommel screens, are a vital component in modern garbage recycling facilities. These machines are designed to sort and separate waste materials efficiently, allowing for more effective recycling and resource recovery. In this article, we'll explore the structure, working principle, applications, advantages, and impact of drum screens in garbage recycling.

Structure of a Drum Screen

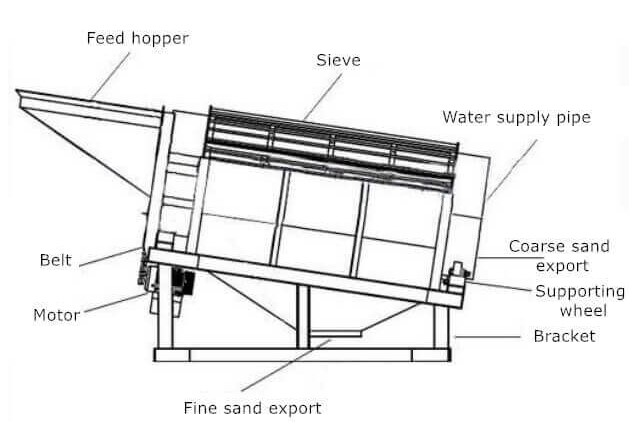

The drum screen is primarily made up of a rotating cylindrical drum, a feeding system, support structure, motor, and discharge outlets. Each component plays a specific role in the separation process:

Rotating Drum: The heart of the drum screen is a large, cylindrical drum with mesh openings of various sizes. As the drum rotates, waste materials are separated based on their size, with smaller particles falling through the mesh and larger pieces being carried to the end of the drum.

Feeding System: Waste materials are fed into the drum screen through a hopper or conveyor. This system ensures a steady flow of waste into the drum, minimizing clogs and maximizing the efficiency of the sorting process.

Support Structure: The drum is mounted on a sturdy support frame that maintains stability during operation. This structure also helps to reduce vibrations and ensures smooth rotation.

Motor and Transmission Device: A powerful motor drives the rotation of the drum at a specific speed, facilitating the tumbling action that enables the sorting process.

Discharge Outlets: Separated materials are discharged through different outlets based on their size. Smaller items pass through the screen holes, while larger items are expelled from the end of the drum.

Impact of Drum Screens on Recycling Efficiency

The use of drum screens in garbage recycling has significantly improved the efficiency and effectiveness of waste processing. They help streamline recycling operations by quickly separating recyclable materials from non-recyclable waste. This not only reduces the workload on manual labor but also increases the purity of recycled materials, leading to higher-quality end products.

In conclusion, drum screens are a key piece of equipment in garbage recycling facilities. Their ability to efficiently separate materials based on size, break down agglomerated waste, and handle a variety of waste types makes them indispensable in the recycling industry. As the focus on sustainability and waste reduction grows, the importance of drum screens in creating a cleaner, greener future cannot be overstated.

Drum screen parameter:

| Model | Screen Size (mm) | Feeding Size (mm) | Drum Diameter (mm) | Drum Length (mm) | Capacity (t/h) | Power (kW) |

| GT0513 | ≤20 | ≤80 | 500 | 1300 | 1-5 | 3 |

| GT0813 | ≤20 | ≤80 | 800 | 1300 | 5-10 | 4 |

| GT1015 | ≤20 | ≤80 | 1000 | 1500 | 10-15 | 5 |

| GT1020 | ≤25 | ≤80 | 1000 | 2000 | 15-20 | 5.5 |

| GT1225 | ≤25 | ≤100 | 1200 | 2500 | 20-50 | 7.5 |

| GT1530 | ≤25 | ≤100 | 1500 | 3000 | 40-70 | 11 |

| GT1545 | ≤25 | ≤100 | 1500 | 4500 | 70-100 | 15 |

| GT1848 | ≤50 | ≤100 | 1800 | 4800 | 100-150 | 22 |

| GT2055 | ≤50 | ≤100 | 2000 | 5500 | 150-200 | 30 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-18Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2024-10-23Solid waste recycling plantOur company engaged in waste sorting system . We are professional about waste sorting system . We have professional technical team. Professional technical team...

-

2024-08-07Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.

-

2023-01-12Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...