How to make domestic waste efficient recycling--RDF Rod Making Machine

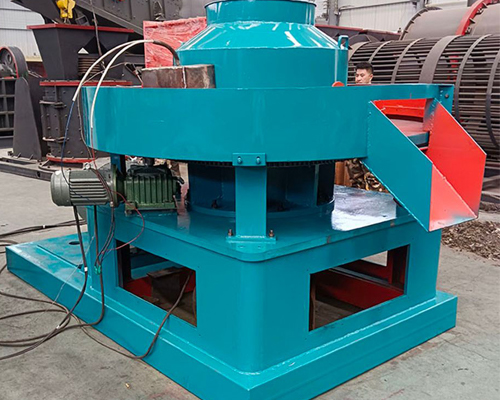

1) RDF Rod Making Machine is a material energy pretreatment equipment.

The following is a detailed introduction about it:

Working principle:

1. RDF Rod Making Machine consists of feeding conveyor, compressor and discharging machine. The compressor part includes frame, motor, feeding port, transmission system, pressing roller, ring die, electric heating ring, discharging port, etc.

2. First, pre-treat the materials to be pressed (such as wood chips, straw, rice husk, bark, cloth strips, leather, garbage, etc.) to make their length less than 50mm and the moisture content within the range of 10%-25%. The material is fed into the feeding port through the feeding conveyor, and the pressing roller is driven to rotate by the rotation of the main shaft. The pressing roller rotates by itself to force the material to be squeezed out of the model hole in blocks and fall from the discharging port. Finally, it is solidified into a high-density rod-shaped solid fuel.

2) Advantages:

1. Resource recycling and reuse: effectively reduce the amount of garbage entering the landfill and promote resource recycling.

2. Reduce environmental pollution: Compared with direct incineration of untreated garbage, RDF reduces harmful emissions due to its more controllable composition.

3. Economic benefits: For enterprises and local governments, selling RDF can generate additional income; at the same time, it can save the cost of disposing of garbage.

4. High flexibility: The production process parameters can be adjusted according to different needs to produce products that meet specific requirements.

5. Promote sustainable development: It helps to build a low-carbon economic system and promote the transformation of society towards a more environmentally friendly direction.

3). Application areas:

1. Cement industry: As one of the raw materials to replace traditional fossil fuels, it is used to heat kilns in the cement production process.

2. Power plants: Some power plants equipped with special incineration facilities can directly use RDF as the main or auxiliary energy source.

3. Heating system: Suitable for places where biomass boilers are used to provide heating services, such as community centralized heating projects.

4. Other industrial uses: In addition to the above industries, any enterprise that requires high-temperature processing and can accept non-traditional fuel forms is a potential user.

4).Parameter:

| Model | Number of molds (blocks) | Molded Fuel Specifications (mm) | Capacity(t/h) | Motor(Kw) |

| GPM-52 | 52 | 32×32 | 0.8-2.5 | 75-160 |

| GPM-102 | 102 | 32×32 | 2.5-6.0 | 160-200 |

| GPM-136 | 136 | 32×32 | 3.5-8.0 | 185-250 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-12The Advantages of Horizontal Baling TechnologyA horizontal baler, also known as a horizontal baling machine, is a piece of equipment used for compressing materials and wrapping them into bales. This process...

-

2024-06-08Solutions for Jaw Crusher ProblemsJaw crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive stren...

-

2024-04-25Recycling Finger ScreensFinger screen is a type of screening equipment used to separate materials based on size. Unlike traditional screens, finger screens consist of a series of paral...

-

2024-07-09Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...

-

2024-08-22Medical waste shredderWorking Principle:Feeding Mechanism: Medical waste is fed into the shredder through a hopper or chute. The feeding mechanism ensures that the waste is introduce...