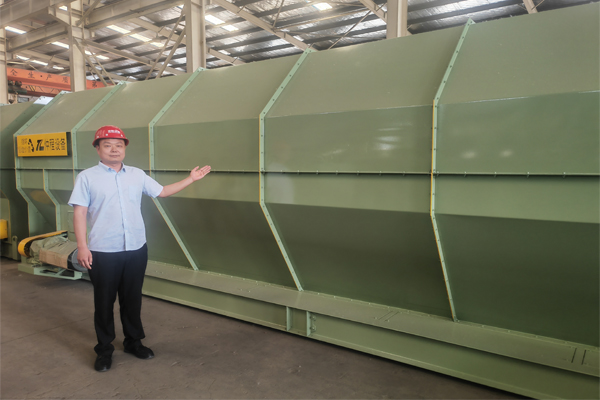

High-Performance Drum Screening Machines

A trommel screen is a cylindrical, rotating screen commonly used in waste sorting plants to

separate materials based on size. Its primary function is to enhance the efficiency of sorting

and recycling processes by allowing smaller particles to pass through its perforations while

retaining larger items for further sorting.

Key Features of Trommel Screens:

Cylindrical Design: The screen is a large, inclined, rotating drum with perforations. The

inclination and rotation allow materials to move through the drum naturally under gravity.

Perforations: The drum has holes of varying sizes to accommodate different material types

and sorting needs. Smaller materials fall through the holes, while larger ones exit at the

drum's end.

Material Flow: The rotation of the drum, combined with its angled placement, ensures

efficient movement and screening of waste materials.

Working Principle:

Waste is fed into the trommel at one end.

As the drum rotates, smaller particles fall through the perforations.

Larger items continue along the length of the drum and are discharged at the other end for

further sorting or processing.

Applications in Waste Sorting:

Municipal Solid Waste (MSW): Trommel screens separate organic waste, recyclables

(like plastics and metals), and residue.

Construction and Demolition Waste: They help sort fine materials like soil or sand from

larger debris such as bricks and concrete.

Composting: They are used to screen compost to remove non-organic contaminants and

produce uniform compost particles.

Advantages:

High Efficiency: Effectively separates materials by size.

Low Maintenance: Simple mechanical design reduces operational issues.

Customizable: Perforation size and drum length can be tailored to specific sorting needs.

Durable: Built to handle abrasive and heavy materials in tough working conditions.

Limitations:

Limited Precision: Only separates by size, so additional sorting methods are often required.

Potential for Clogging: Moist or sticky materials can clog the perforations.

Energy Use: Rotating the drum requires energy, though modern designs aim to improve

energy efficiency.

In summary, a trommel screen is a vital component in waste sorting plants, significantly contributing

to the separation and processing of materials for recycling and disposal.

a trommel screen can be used in many fields beyond waste sorting, thanks to its versatile design

and effective separation capabilities. Here are some of the common fields where trommel screens

are applied:

1. Waste Management

Municipal Solid Waste (MSW): Separates recyclables, organic waste, and residual waste.

Construction and Demolition Waste: Removes fine materials like soil from rubble, bricks, and

other debris.

Landfill Mining: Screens out usable materials during landfill reclamation.

2. Recycling Industry

Plastic Recycling: Sorts plastics by size and removes contaminants.

Metal Recycling: Separates metals from other waste for easier processing.

Electronic Waste: Used to classify and separate components for recycling.

3. Composting

Screens compost to remove unwanted materials and achieve a uniform particle size for mature compost.

4. Mining and Quarrying

Mineral Processing: Separates ore based on size for further processing or direct use.

Gravel and Sand Processing: Screens materials to obtain desired size fractions.

5. Agriculture

Soil Screening: Removes rocks and debris from soil for farming or landscaping purposes.

Grain Processing: Separates grains from husks or other unwanted materials.

6. Forestry and Biomass

Wood Processing: Screens wood chips and sawdust for use in biomass energy production.

Biomass Fuel: Separates usable biomass materials from non-combustible waste.

7. Industrial Processes

Chemical Production: Screens raw materials or intermediates in chemical manufacturing.

Food Industry: Used to sort and separate items like nuts, seeds, or powders.

8. Environmental Applications

Soil Remediation: Separates contaminated soil particles for treatment or disposal.

Water Treatment: Used in some systems to separate solids from water.

Advantages of Multi-Field Use:

Customizability: Trommel screens can be tailored to specific material sizes and requirements,

making them versatile across industries.

Efficiency: They are highly effective at separating materials quickly and with minimal human

intervention.

Durability: Designed to handle heavy-duty applications in various environments.

The adaptability of trommel screens makes them a valuable tool across many industries,

contributing to resource recovery, recycling, and efficient material processing.

Trommel Screen Parameter Sheet

| Model | Length Range | Segment No. | Aperture Size | Power (Kw) | Inclined Angle | Max. Material Size | Rotating Speed(rpm) |

| ZCφ600 | 2-4m | 1-2 | ≤30mm | 2.2-3 | 0-7° | 60mm | 12-18 |

| ZCφ800 | 2-5m | 1-3 | ≤50mm | 3-5.5 | 0-7° | 100mm | 12-18 |

| ZCφ1000 | 2-6m | 1-4 | ≤100mm | 4-11 | 0-7° | 150mm | 10-18 |

| ZCφ1200 | 3-8m | 1-4 | ≤150mm | 5.5-18.5 | 0-7° | 200mm | 9-15 |

| ZCφ1500 | 3-10m | 1-5 | ≤200mm | 7.5-22 | 0-7° | 250mm | 9-15 |

| ZCφ1800 | 4-12m | 1-5 | ≤220mm | 7.5-22 | 0-7° | 270mm | 8-15 |

| ZCφ2000 | 5-15m | 1-5 | ≤250mm | 11-30 | 0-7° | 300mm | 8-12 |

| ZCφ2500 | 5-18m | 1-6 | ≤300mm | 11-30 | 0-7° | 350mm | 8-12 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-08Solutions for Jaw Crusher ProblemsJaw crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive stren...

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2024-08-16Crop straw double shaft shredderApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...

-

2023-01-12Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...

-

2023-01-18RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...