A magnetic separator is a critical component in a solid waste sorting plant

A magnetic separator is a critical component in a solid waste sorting plant. Its primary purpose

is to separate ferrous materials (metals containing iron) from the waste stream. This process

enhances recycling efficiency, reduces contamination, and ensures proper material recovery.

Below is an overview of its concept and operation:

Principle of Operation

A magnetic separator uses a magnetic field to attract ferrous metals from a mixture of waste

materials. Non-magnetic materials (such as plastics, glass, and organic matter) pass through

unaffected, while magnetic metals (like steel and iron) are extracted.

Key Components

Magnetic System: A strong magnet or an electromagnet generates the magnetic field.

The type of magnet (permanent or electromagnet) depends on the specific application and

material characteristics.

Conveyor Belt or Drum: A moving system, such as a belt or rotating drum, carries waste

material through the magnetic field.

Discharge Systems: Separate outlets are provided for ferrous and non-ferrous materials,

enabling easy collection and sorting.

Types of Magnetic Separators

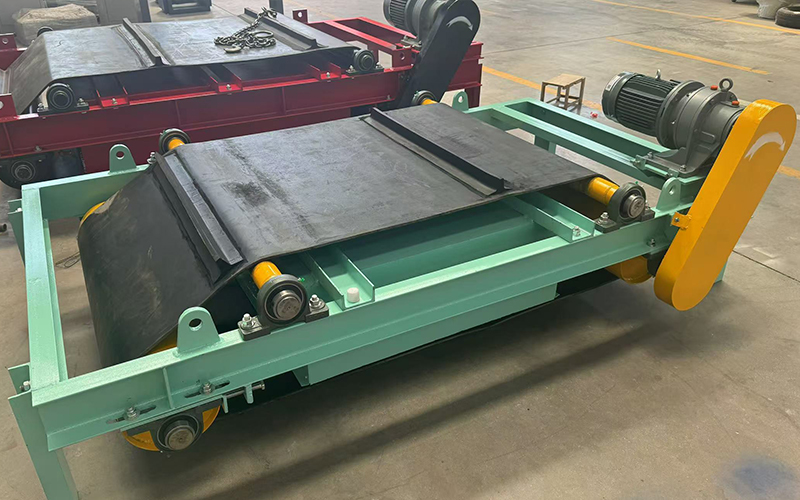

Overband Magnetic Separator:

Installed over a conveyor belt.

Removes ferrous metals as the waste moves underneath.

Drum Magnetic Separator:

Cylindrical drum with a magnetic surface rotates through the waste stream.

Ferrous metals stick to the drum and are carried to a separate discharge point.

Eddy Current Separator:

Often combined with magnetic separators.

Separates non-ferrous metals (like aluminum) using an induced magnetic field.

Magnetic Pulley:

A pulley at the end of a conveyor belt with a magnetic core.

Pulls ferrous metals from the material stream.

Advantages

Efficient Material Recovery: Ensures high recovery rates for ferrous metals.

Reduces Waste Volume: Diverts recoverable metals from landfills.

Cost Savings: Decreases disposal costs and generates revenue from recycled metals.

Protects Equipment: Removes sharp or hazardous metal objects that could damage downstream machinery.

Applications

Municipal Solid Waste (MSW) sorting plants.

Construction and Demolition (C&D) waste recycling.

Electronic Waste (e-waste) processing.

Automotive Recycling.

In conclusion, magnetic separators are indispensable for sustainable waste management, ensuring the efficient recovery of valuable resources while reducing environmental impact.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-05Can the Angle of the Ballistic Separator Be Adjusted?Ballistic separator is a type of mechanical sorting device used primarily in the recycling industry to separate materials based on their physical properties. It...

-

2024-05-18Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...

-

2024-06-06Drum Screen For Composting PlantDrum screen, also known as a rotary drum screen or trommel screen, is an essential piece of equipment used in composting plants for the separation of compost ma...

-

2023-01-12Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...

-

2024-08-07Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.