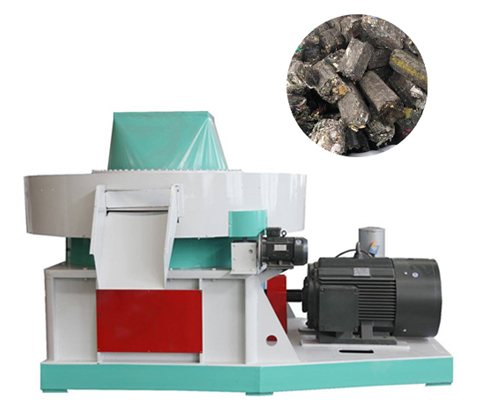

How Does RDF Rod Making Machine Turn Waste into Treasure

1). RDF rod making machine is a kind of equipment that converts various biomass and solid waste into high-density rod-shaped fuel. The following is a detailed introduction for you:

2). Working principle

1. Raw material pretreatment: First, the biomass or solid waste is crushed and pretreated to make the raw material size below 50mm, and the moisture content is controlled at about 10%-25% to meet the requirements of rod making.

2. Compression molding: The pretreated material is fed into the feed port of the rod making machine, and the main shaft rotates to drive the roller to rotate. When the roller rotates, the material is forced to be squeezed out of the model hole to form a block or rod-shaped solid fuel, and falls from the discharge port.

3). Main structural components

1. Frame: As the supporting structure of the entire equipment, it ensures the stability of the equipment and the safety during operation.

2. Transmission system: generally composed of motor, reducer, transmission shaft, gear, etc., responsible for transmitting power to working parts such as pressure rollers, so that the equipment can operate normally.

3. Feeding device: including feed port, screw conveyor, etc., its function is to evenly convey materials to the compression molding part to ensure the continuity and stability of material supply.

4. Compression molding parts: mainly composed of pressure rollers and ring molds, which are the core working parts of RDF rod making machine. The roller rolls in the ring die, exerting pressure on the material, so that it is compressed and formed in the die hole of the ring die.

5. Discharging device: used to smoothly discharge the formed rod-shaped fuel from the equipment, and collect and subsequently process it.

4). Performance advantages

1. Wide adaptability of raw materials: a variety of biomass and solid waste such as sawdust, straw, rice husk, bark, cloth strips, leather, garbage, etc. can be used as raw materials, effectively utilizing resources, reducing production costs, and realizing the resource utilization of waste.

2. Good fuel performance: The particles after briquetting have a large specific gravity and small volume, which is easy to store and transport. It is a high-volatile solid fuel with a calorific value of 3200-4000 kcal. It is flammable and has low ash content. It can replace firewood, raw coal, gas and other fuels. It is widely used in heating, domestic stoves, boilers, biomass power plants and other places.

3. High production efficiency: using advanced design and manufacturing technology, the main drive of some equipment adopts high-precision gear drive, and the output is 20% higher than that of belt drive About 1000 tons, which can meet the needs of large-scale production.

4. Significant environmental benefits: By converting waste into fuel, the amount of landfill and incineration is reduced, and the pollution to the environment is reduced; at the same time, the pollutant emissions after the combustion of RDF fuel are relatively low, which is beneficial to environmental protection.

5. Stable and reliable operation: The equipment has a reasonable structure, and the key components are made of high-quality materials with good wear resistance and corrosion resistance. After strict quality inspection and debugging, the stability and reliability of the equipment during long-term operation are guaranteed, and the maintenance cost and downtime of the equipment are reduced.

6. Easy operation and maintenance: The equipment has a high degree of automation, and the operation is simple and convenient. It can be operated proficiently after short-term training; at the same time, the maintenance of the equipment is also relatively easy. Daily inspection and regular maintenance can effectively extend the service life of the equipment.

5). Application fields

1. Biomass energy field: Agricultural and forestry wastes are made into biomass fuel rods for biomass power generation, heating, etc., to provide clean energy for society and reduce dependence on traditional fossil energy.

2. Waste treatment field: The combustible part of urban domestic waste can be made into RDF fuel rods to achieve waste reduction, resource utilization and harmless treatment, relieve the pressure of landfills, and reduce the impact of waste treatment on the environment.

3. Industrial solid waste treatment field: For some solid wastes generated in industrial production processes, such as papermaking waste residue, washing plant waste residue, textile waste, leather waste, etc., they are processed through RDF rod making machines and converted into valuable fuels, realizing the recycling of industrial solid wastes and reducing the production costs and environmental risks of enterprises.

6). Parameter

Model | Power(KW) | Capacity(T/H) | Mold quantity | Roll quantity | Over dimension(MM) |

9JK-2600 | 75 | 1-2 | 52 | 2 | 2647*2100*1900 |

9JK-3500 | 110 | 2-3 | 72 | 2 | 3250*2600*2000 |

9JK-4500 | 132 | 3-4 | 88 | 2 | 3350*2800*2200 |

9JK-5000 | 160 | 4-5 | 100 | 2 | 3000*2300*2000 |

9JK-5500 | 160 | 4-5 | 102 | 2 | 3000*2400*2000 |

9JK-6500 | 200 | 4-5 | 120 | 3 | 4400*2970*2495 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-09Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...

-

2023-01-12Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...

-

2024-05-18Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...

-

2023-01-12Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...