Subverting traditional screening techniques: Efficient bouncing screens usher in a new era of material separation

A bouncing screen, also known as a vibrating screen or a jumping screen, is a piece of industrial equipment used for sorting and screening materials in various industries such as mining, quarrying, recycling, and construction. The primary function of a bouncing screen is to separate materials based on size, removing fines (small particles) from larger pieces.

How It Works:

The mechanism of a bouncing screen typically involves a screen box that is vibrated or shaken to move the material across its surface. This vibration can be achieved through different methods, including:

- Mechanical Drives: Using eccentric shafts or weights to create a circular or linear motion.

- Electromagnetic Drives: Utilizing electromagnetic forces to produce high-frequency vibrations.

Pneumatic Systems: Air pressure can be used to cause the screen to bounce or vibrate.

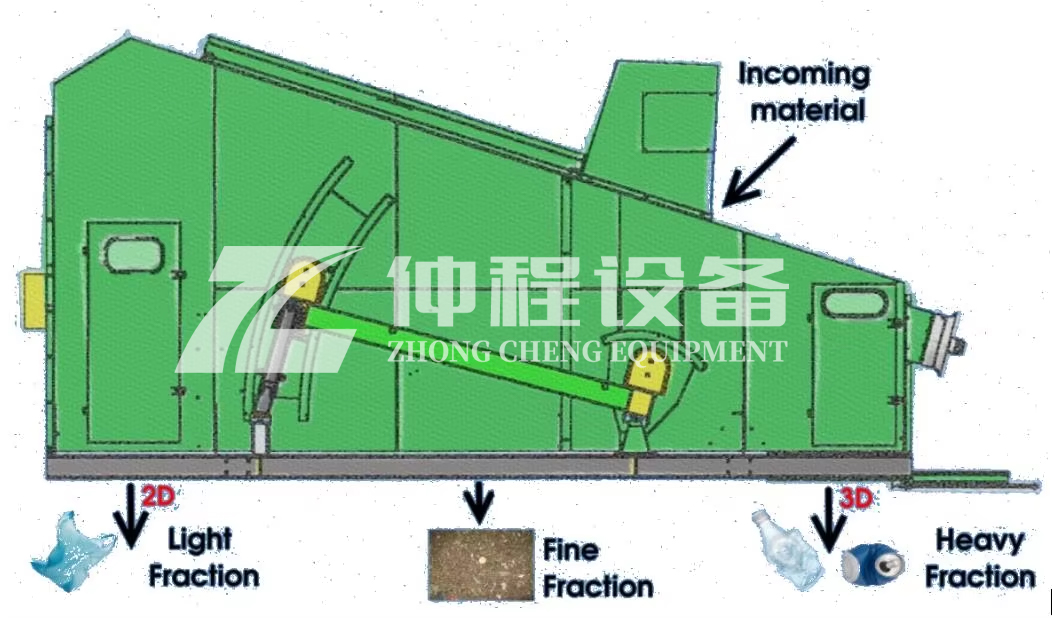

As the material moves across the screen, smaller particles fall through the openings (apertures) while larger particles remain on top. The angle of the screen and the intensity of the vibrations can be adjusted to optimize the separation process for different materials and particle sizes.

Applications:

Bouncing screens are versatile and can be used in a wide range of applications, such as:

- Mining: Separating ore from waste rock.

- Quarrying: Grading crushed stone and gravel.

- Recycling: Sorting mixed waste materials like plastics, metals, and paper.

- Agriculture: Cleaning seeds and grading agricultural products.

Food Processing: Sifting flour, sugar, and other food ingredients.

Benefits:

- Efficiency: Bouncing screens can handle large volumes of material quickly and effectively.

- Adjustability: The settings can be fine-tuned to suit specific requirements.

- Durability: Built to withstand harsh conditions and heavy use.

Cost-Effective: Reduces labor costs and improves production efficiency.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...

-

2023-01-12Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...

-

2023-01-11Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.

-

2024-05-28Garbage screening drum screenTrommel screen is consisting of five parts: drum, frame, hopper, reducer and motor.After the material goes into the drum, it is screened along with the rotation...

-

2024-08-20A rubber double shaft shredderExamples of Specific Models:GDB Series Biomass Shredder: Although primarily designed for biomass materials, this model can also be configured to handle various ...