RDF (Refuse Derived Fuel) Rod Making Machine

1). RDF (Refuse Derived Fuel) rod making machine is a kind of equipment specially used to convert waste into solid fuel rods. This technology is mainly used in the field of waste disposal and resource recovery, which can effectively reduce the amount of landfill and produce environmentally friendly energy products that can replace traditional fossil fuels. The following is a detailed introduction to the RDF rod making machine:

2). Working principle

The RDF rod making machine uses physical methods to crush, screen, mix, and shape various wastes (such as domestic waste, industrial waste, agricultural and forestry residues, etc.) through a series of processes such as crushing, screening, mixing, and molding, and finally presses them into solid fuel rods with a certain density and shape. These fuel rods are widely used in power plants, boilers and other occasions due to their high combustion efficiency and low environmental pollution.

2. Main components

1. Feeding system: responsible for feeding raw materials into the machine for preliminary processing.

2. Crushing device: finely crush the raw materials to meet the requirements of subsequent processing.

3. Screening device: remove impurities in the raw materials to ensure product quality.

4. Mixing device: add adhesives or other additives as needed to mix the raw materials evenly.

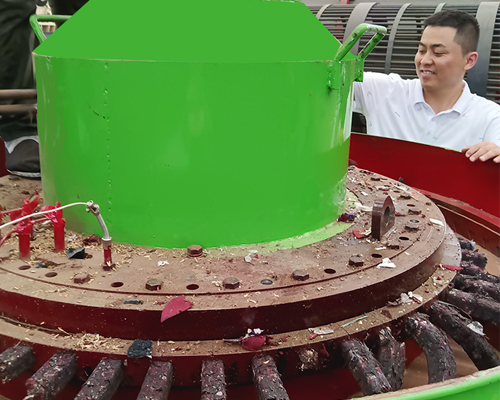

5. Molding device: It is the core part, which uses high pressure to compress the mixed raw materials into the required shape of fuel rods.

6. Cooling system: The molded fuel rods need to be cooled to stabilize their shape and avoid deformation.

7. Control system: Realize the automatic control of the entire production process, improve production efficiency and yield rate.

3). Application advantages

1. Environmental protection: It effectively reduces the environmental pollution caused by the accumulation and incineration of waste.

2. Energy saving: The RDF fuel rods produced can replace some traditional fossil fuels, which helps to reduce energy costs and carbon emissions.

3. Economic benefits: Through waste recycling, it not only solves the problem of garbage disposal, but also creates new economic value.

4). Precautions

When using the RDF rod making machine, it is necessary to pay attention to the selection and pretreatment of raw materials to ensure the cleanliness and suitability of the raw materials to ensure the quality and performance of the final product. In addition, regular maintenance and inspection of equipment are also the key to ensure smooth production.

5). Model

Model | Power(KW) | Capacity(T/H) | Mold quantity | Roll quantity | Over dimension(MM) |

9JK-2600 | 75 | 1-2 | 52 | 2 | 2647*2100*1900 |

9JK-3500 | 110 | 2-3 | 72 | 2 | 3250*2600*2000 |

9JK-4500 | 132 | 3-4 | 88 | 2 | 3350*2800*2200 |

9JK-5000 | 160 | 4-5 | 100 | 2 | 3000*2300*2000 |

9JK-5500 | 160 | 4-5 | 102 | 2 | 3000*2400*2000 |

9JK-6500 | 200 | 4-5 | 120 | 3 | 4400*2970*2495 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-18C Series Jaw CrusherC series jaw crusher is a jaw crusher with excellent performance introduced and developed by zchmachinery according to the market demand. Compared with traditio...

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...

-

2024-07-16Drum screen garbage processing machine for msw recyclingManaging municipal solid waste (MSW) efficiently is crucial for urban areas. Drum screen garbage processing machines are a game-changer in this field. They ensu...

-

2023-01-12Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...

-

2024-08-28Scrap rubber product shredderThe shredder of waste rubber products not only helps to reduce environmental pollution, but also improves the reuse rate of waste rubber, which is one of the im...