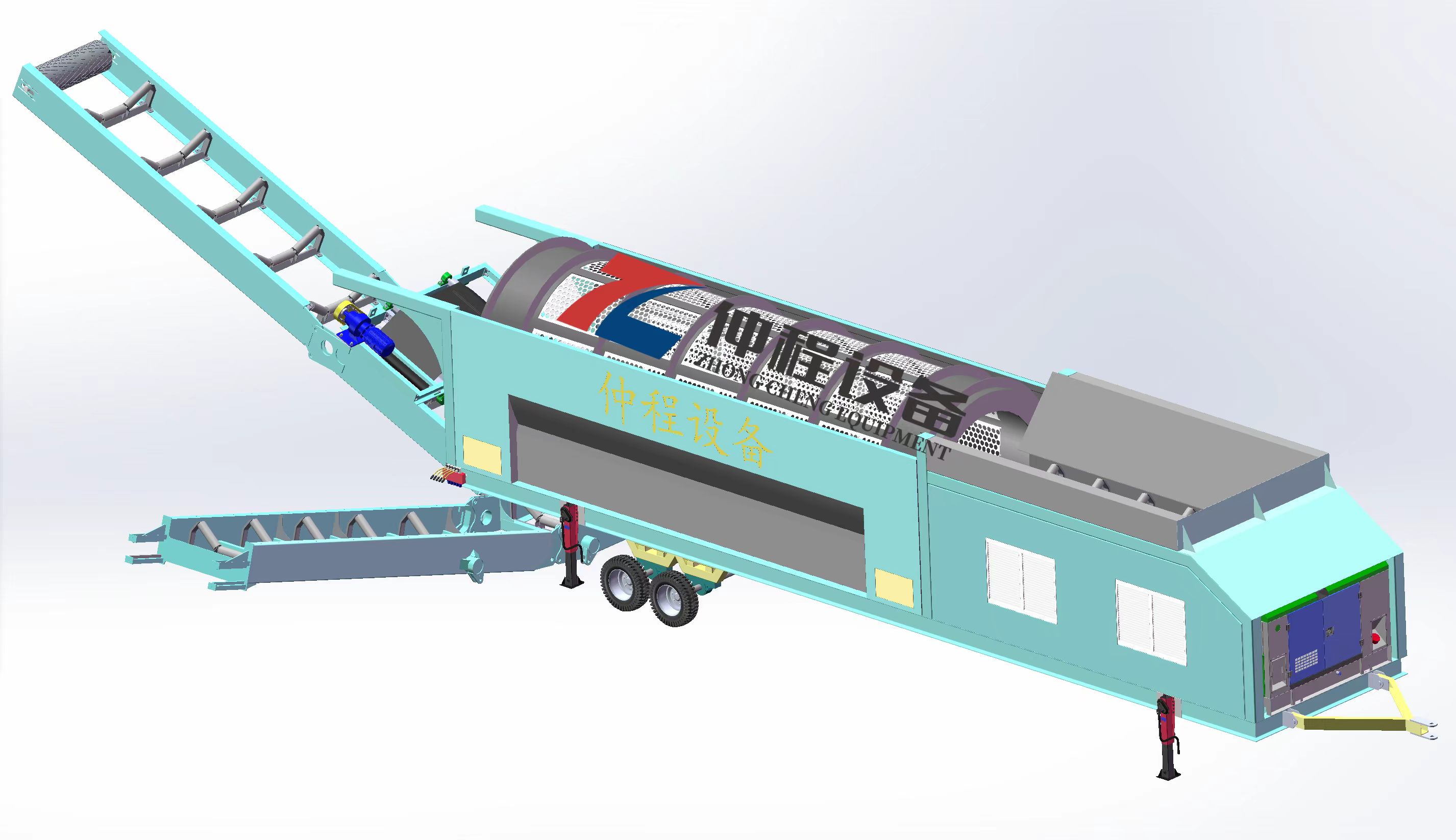

A base equipments of msw sorting plant--trommel screen

What is a Trommel Screen?

A trommel screen, also known as a rotary screen,

is a mechanical screening machine used to separate materials,

primarily in the mineral and solid-waste processing industries.

It consists of a cylindrical drum with perforated holes of varying sizes,

through which materials are sorted by size as the drum rotates.

When the material enters the drum device,

due to the inclination and rotation of the drum device,

the material on the screen surface is turned over and rolled,

so that the under-screen material smaller than the screen hole

size is discharged from the screen hole,

and the screened material larger than the screen hole size is

discharged from the tail through the drum.

Key Features

Trommel screens are characterized by their unique design and operational features:

Rotating Drum: The heart of the trommel screen, it ensures continuous and efficient screening of materials.

Perforated Holes: Available in various sizes to accommodate different material separation requirements.

Variable Speed: Allows adjustment of the drum rotation speed to optimize screening performance.

Durable Construction: Built with high-quality materials to withstand heavy-duty use and harsh environments.

Ease of Maintenance: Designed for easy access and cleaning to ensure minimal downtime.

Applications of Trommel Screens

Trommel screens are used in a wide range of industries due to their versatility and effectiveness. Common applications include:

Recycling: Sorting and separating recyclables such as plastics, metals, and glass by size for efficient processing.

Mining: Separating valuable minerals from ore based on size, improving the efficiency of downstream processing.

Waste Management: Screening and separating different types of waste materials, facilitating more efficient recycling and disposal.

Agriculture: Separating organic materials, such as compost and topsoil, from unwanted debris.

Construction: Sorting construction and demolition debris, such as rubble, sand, and gravel, by size.

Benefits of Using Trommel Screens

Implementing trommel screens in material separation processes offers numerous benefits:

Increased Efficiency: Enhances the speed and accuracy of material separation, reducing manual sorting time.

Improved Product Quality: Ensures consistent and high-quality separation of materials, leading to better end products.

Cost Savings: Reduces labor costs and increases operational efficiency, leading to overall cost savings.

Scalability: Easily integrated into existing operations and can be scaled up as processing needs grow.

Environmental Impact: Efficient material separation supports recycling efforts, reducing waste and conserving resources.

Parameter sheet of trommel screen

| Model | Length Range | Segment No. | Aperture Size | Power (Kw) | Inclined Angle | Max. Material Size | Rotating Speed(rpm) |

| ZCφ600 | 2-4m | 1-2 | ≤30mm | 2.2-3 | 0-7° | 60mm | 12-18 |

| ZCφ800 | 2-5m | 1-3 | ≤50mm | 3-5.5 | 0-7° | 100mm | 12-18 |

| ZCφ1000 | 2-6m | 1-4 | ≤100mm | 4-11 | 0-7° | 150mm | 10-18 |

| ZCφ1200 | 3-8m | 1-4 | ≤150mm | 5.5-18.5 | 0-7° | 200mm | 9-15 |

| ZCφ1500 | 3-10m | 1-5 | ≤200mm | 7.5-22 | 0-7° | 250mm | 9-15 |

| ZCφ1800 | 4-12m | 1-5 | ≤220mm | 7.5-22 | 0-7° | 270mm | 8-15 |

| ZCφ2000 | 5-15m | 1-5 | ≤250mm | 11-30 | 0-7° | 300mm | 8-12 |

| ZCφ2500 | 5-18m | 1-6 | ≤300mm | 11-30 | 0-7° | 350mm | 8-12 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...

-

2024-10-23Solid waste recycling plantOur company engaged in waste sorting system . We are professional about waste sorting system . We have professional technical team. Professional technical team...

-

2024-06-05Waste Trommel And Copmost TrommelHowever, it's important to choose the right type of drum screen based on your specific needs. Today, Kevin from Zhongcheng Company will explain the differences...

-

2024-05-28Garbage screening drum screenTrommel screen is consisting of five parts: drum, frame, hopper, reducer and motor.After the material goes into the drum, it is screened along with the rotation...