solid waste shredder for mixture waste process

Solid waste shredders come in various sizes and configurations,

ranging from small-scale units suitable for small recycling yard

use to large industrial machines for heavy-duty applications.

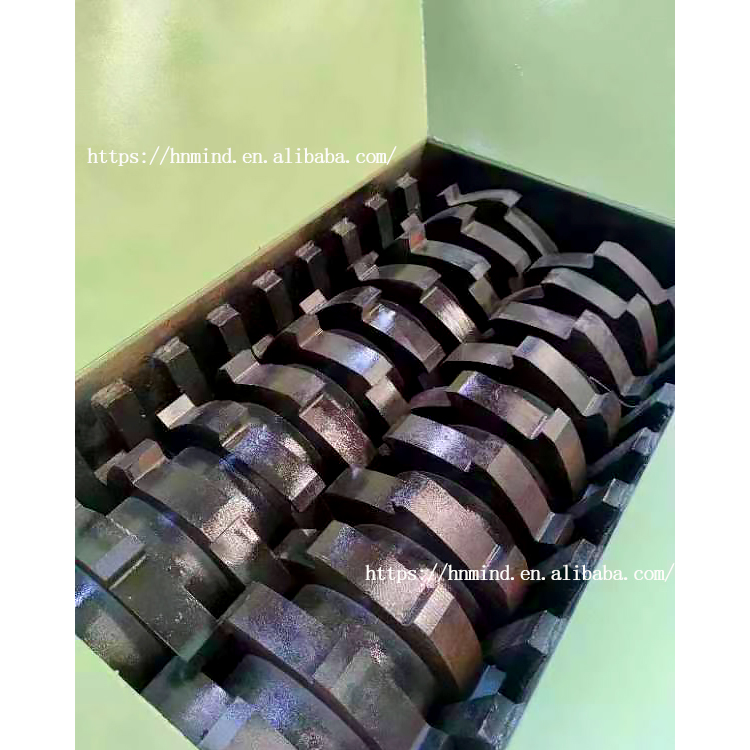

They typically consist of a hopper or feed chamber where the waste is loaded,

rotating blades or hammers that shred the materials,

and a discharge mechanism for the shredded output.

Industrial solid waste shredders can be divided into the following types based on their structure and design:

Single Shaft Shredder

Single shaft shredders consist of a rotating main shaft and blades or hammers that rotate around it.

They are suitable for shredding various types of solid waste materials such as plastic,

wood, scrap metal, rubber, paper, textile, etc.

Double Shaft Shredder

Double shaft shredders have two parallel rotating main shafts, each with blades or hammers.

This structure increases shredding efficiency and capacity, making them suitable for processing

larger and tougher waste materials.

Four Shaft Shredder

Four shaft shredders add two additional rotating shafts to the dual shaft shredder.

Quad shaft shredders provide higher shear force and finer shredding capabilities,

making them suitable for handling waste with higher tensile strength.

These are common types of industrial solid waste shredders based on their structure and design.

The specific choice of shredder type depends on the nature of the waste, shredding requirements,

and processing capacity needed.

As a professional manufacturer of solid waste recycling equipment,

we produce high quality shredding machines. And we can always provide you with the most

suitable machines and customized solutions.

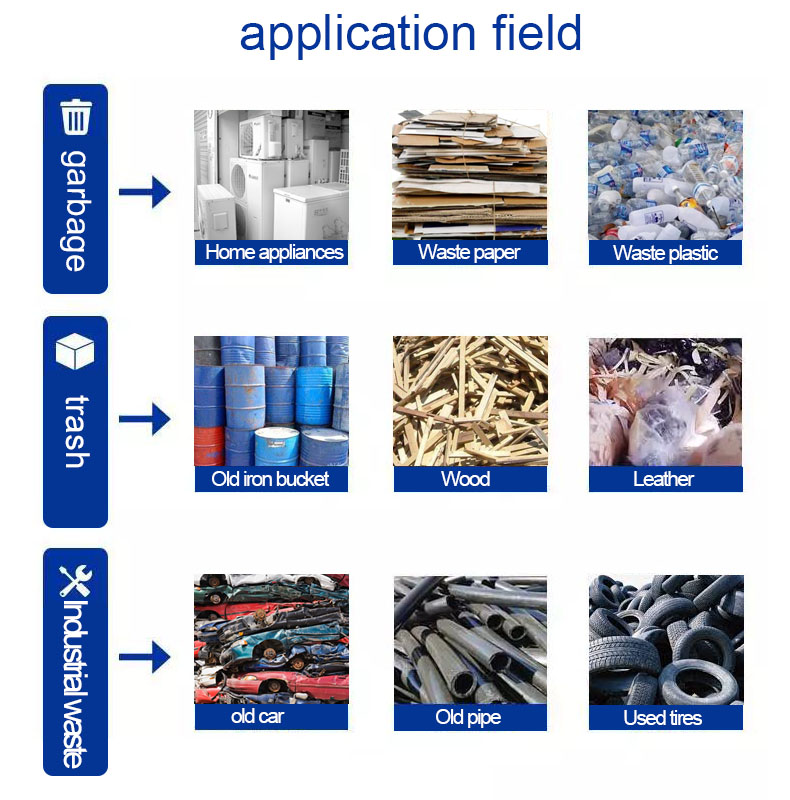

Industrial shredder machines have a wide range of applications.

Here are some applications of industrial shredders:

1. Waste processing and recycling: Industrial shredders are used for processing and recycling various types of waste,

including paper, cardboard, plastic, metal, rubber, wood, etc. Shredding waste reduces its volume and facilitates

further processing and recycling.

2. E-waste processing: Industrial shredders are specifically designed for processing electronic waste, such as electronic devices,

cables, circuit boards, etc. Shredding e-waste ensures secure destruction of sensitive information and allows for the recovery

of valuable metals and other materials.

3. Automotive recycling: Industrial shredders are used in the automotive recycling industry for the processing of

end-of-life vehicles. They shred car parts and metal scraps for recycling purposes.

4. Plastic processing: Industrial shredders are employed in the plastic processing industry for shredding waste

plastic products, plastic molds, pipes, etc., enabling further processing or recycling.

5. Paper manufacturing and printing industry: Industrial shredders are used for waste paper handling in paper manufacturing

and printing industries. Shredding waste paper reduces costs in pulp preparation and promotes efficient resource utilization.

6. Medical waste disposal: Industrial shredders are utilized for the disposal of medical waste, including medical papers, syringes,

medical packaging, etc. Shredding medical waste reduces its volume and prevents the leakage of sensitive information.

7. Metal recycling: Industrial shredders are used for shredding scrap metal products, metal sheets, iron waste, etc.,

facilitating metal recycling and reuse.

8. Plastic bottle and container recycling: Industrial shredders are widely used in the recycling process of plastic bottles

and containers. Shredding waste plastic bottles and containers facilitates storage, transportation, and subsequent recycling.

9. Wood processing and paper industry: Industrial shredders are utilized in the wood processing industry and paper industry

for the shredding of waste wood and cardboard. Shredding waste wood and cardboard reduces volume, lowers costs,

and promotes resource efficiency.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...

-

2024-08-06Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...

-

2024-06-09Advantages of Using Drum Screening Machines in Waste ManagementUnderstanding the working principle of drum screening machines is essential to appreciate their efficiency and effectiveness in waste management. Operation and ...

-

2024-07-10msw trommel screen for waste recycling machineThis equipment is suitable for the particle classification process in all walks of life:The equipment is simple, easy to operate,and can be operated with a larg...

-

2024-04-13Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...