How waste bag openers used in waste sorting plant ?

These waste bag openers are very powerful to be installed at the head of treatment plants

for municipal solid waste.

They are characterized by a high reliability thanks to a treatment

capacity and to couples of considerable magnitude.

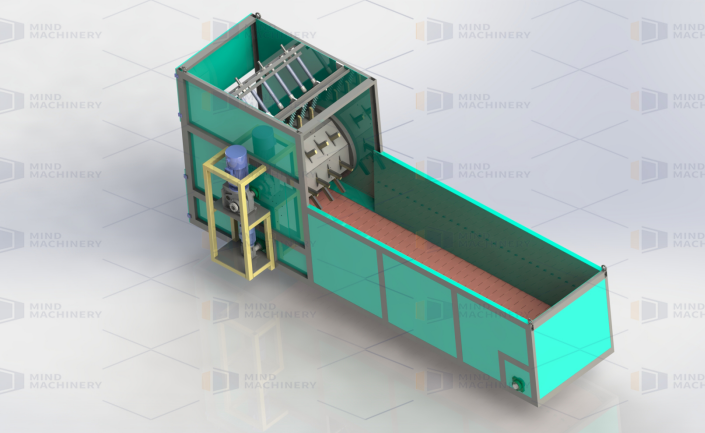

Waste bag openers are innovative and specific machine that allows the opening and emptying

of bags containing the material, the construction method adopted also allows you to rip and

empty 98% of bags introduced without cutting or damaging the contents. The bag opener

ensures optimum opening of bags of different sizes and a constant supply to the following

treatments: it is designed as a modular system, easily adaptable to individual needs.

The machine turns out to be of great reliability and does not require frequent cleaning

operations since equipped with a special system that does not allow the winding of long products

(films, holding, VHS tapes, etc.), around the rotor while keeping the same in conditions of

extreme cleanliness. Furthermore, the conformation of the machine is such as to ensure the

feeding of the downstream plants in an adjustable manner and constant, ensuring for this constancy of production.

ZhongCheng’s bag openers , have electro-hydraulic counter-rotating rotors and are constituted

by a grinding chamber in sturdy electro-welded structure appropriately sized rotors grinding,

inserts cleaners, large planetary gears, support stand and feed hopper. The criterion of operation

allows these bag openers work with the rotors in counter sense and vice versa.

The essential feature of these applications is certainly the sturdiness which together with the

large values of torque applied to trees and to a sophisticated electronic control system pressures,

make these machines a reliable and highly productive. The rotors are equipped with which these

machines are made of alloy steel of prime quality.

Their shape, thickness, and number of knoves are defined in function of the material to be treated

and of the size required at the exit. The control system of the machine is able to adjust the pressure

up to a maximum value, adjusted by the manufacturer, to the above which intervenes a safety

function which reverses the direction of rotation of the rotors to reject the materials too tenacious.

The machine can work with the rotors in clockwise and counterclockwise. In summary this type of

machine is geared to adjusting volume of incoming waste, which is obtained through the process of

continuous shearing of: municipal solid waste as such, waste from waste collection, waste of twigs

and other material to be composted, waste wood, pallets etc.

The uniqueness of this application lies in the fact that these machines do not subject the material to

be treated to a third cut but rather ‘to a break for tearing. Everything ‘are specifically designed for

treatment plants as selection RSU, incineration, waste from waste collection, etc.

The blades of these machines are made of alloy steel and wear.

| BO12 | BO14 | BO16 | BO18 | |

| Width | 1200mm | 1400mm | 1600mm | 1800mm |

| Number of rotors | Two | Two | Two | Two |

| Speed of the main rotor | 0-25 rpm | 0-25 rpm | 0-25 rpm | 0-25 rpm |

| Speed of second rotor | 0-5 rpm | 0-5 rpm | 0-5 rpm | 0-5 rpm |

| Power | 15+5.5kw | 15+5.5kw | 15+7.5kw | 15+7.5kw |

| Throughput | 10-30m³/h | 20-50m³/h | 40-80m³/h | 60-100m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-20A rubber double shaft shredderExamples of Specific Models:GDB Series Biomass Shredder: Although primarily designed for biomass materials, this model can also be configured to handle various ...

-

2024-07-10msw trommel screen for waste recycling machineThis equipment is suitable for the particle classification process in all walks of life:The equipment is simple, easy to operate,and can be operated with a larg...

-

2023-01-12Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...

-

2024-05-18Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...

-

2024-06-07Zhongcheng Air Drum Separator in MSWAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...