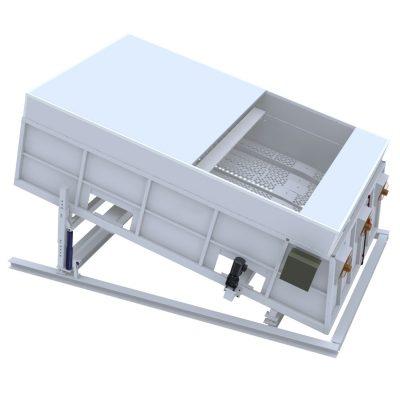

Ballistic Separator

Ballistic Separator

Efficient removal of bulky waste compounds

A solid, inclined screen plate that oscillates sets

the material on it in motion. Heavy and spherical

or cubic parts roll down into the heavy fraction,

which includes unwanted debris – such as stones,

bricks, and other heavy items – that have to be

removed in order to protect the downstream equipment in

a reject line. Furthermore, this fraction includes very

valuable compounds, such as plastic bottles or cans.

All flat and light particles – such as plastics, sheets of

paper – move upwards towards the light fraction.

The screen plate (sieve) creates a fine fraction.

We can process wet material (with consistencies down to 20%)

and has a high throughput of up to 60 m³/h. The machine is

manufactured in-house and has already been applied in several reject lines .

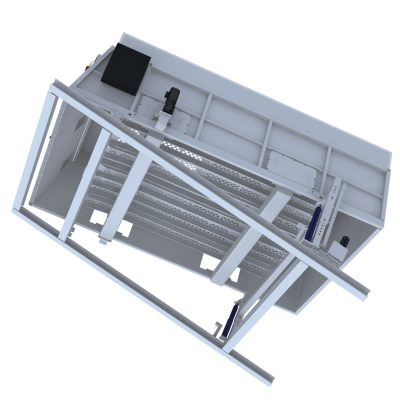

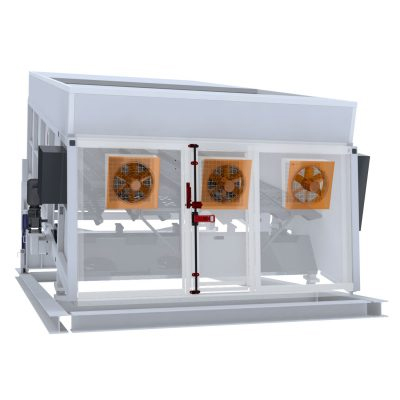

Benefits of Ballistic Separator

1,Closed system for clean machine environment

2,Various adjustment possibilities (e.g. angle of inclination, machine 3,speed) and screen plates

4,High throughput up to 60 m³/h

5,Low energy consumption

6,Gas-spring-supported maintenance openings ensure easy accessibility

Widely known for their reliability and efficiency, wide range of ballistic separators are used in RSU,

EELL and CSR plants. There is the possibility to adjust different parameters in order to adapt

automatically the type of material, from the fan speed to the equipment slope.

The equipment is especially designed to make cleaning and maintenance easier,

and it is supplied with different devices which make the inside of the ballistic as

ergonomic and comfortable as possible.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-04-13Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...

-

2024-05-18Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...

-

2024-06-06Drum Screen For Composting PlantDrum screen, also known as a rotary drum screen or trommel screen, is an essential piece of equipment used in composting plants for the separation of compost ma...

-

2024-07-09Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...

-

2024-08-07Tire double shaft shredderOperation:Feeding: Whole or pre-cut tires are fed into the shredder through an inlet hopper.Shredding: As the tires enter the shredding chamber, the rotating cu...