What's ballistic separator function in waste sorting system

What's ballistic separator function in waste sorting system ?

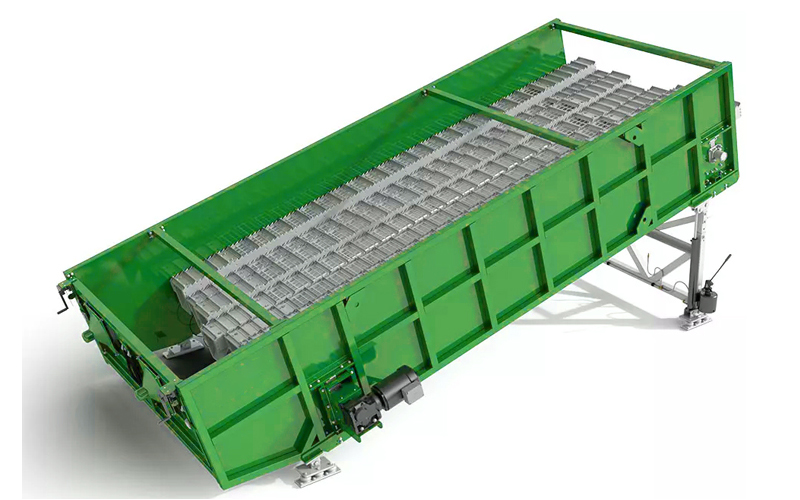

A ballistic separator in a waste sorting plant is a specialized machine used to separate

waste materials based on their physical characteristics, such as density, shape, and size.

It plays a critical role in modern waste management by improving the efficiency of sorting

processes and enhancing the quality of recyclables.

Working Principle:

The ballistic separator operates on the principle of motion and gravity to classify waste into

different fractions:

- Input: Mixed waste is fed onto the ballistic separator.

Inclined or Perforated Plate: The machine consists of an inclined or vibrating surface

with perforations and paddles.

- Separation:

Flat, Lightweight Materials (e.g., paper, plastic film): These are "bounced" forward

due to their shape and low density.

Heavy, Rigid Materials (e.g., glass, cans, stones): These roll backward or stay on

the surface due to their higher weight and density.

Small Particles (e.g., dust, debris): These pass through perforations in the separator

plate.

Working Principle:

The ballistic separator operates on the principle of motion and gravity to classify waste into

different fractions:

Input: Mixed waste is fed onto the ballistic separator.

Inclined or Perforated Plate: The machine consists of an inclined or vibrating surface with

perforations and paddles.

Separation:

Flat, Lightweight Materials (e.g., paper, plastic film): These are "bounced" forward due to their

shape and low density.

Heavy, Rigid Materials (e.g., glass, cans, stones): These roll backward or stay on the surface

due to their higher weight and density.

Small Particles (e.g., dust, debris): These pass through perforations in the separator plate.

Fractions Produced:

2D Materials: Flat, lightweight items like paper, cardboard, and plastic film are moved forward.

3D Materials: Bulky, rigid objects like bottles, cans, and containers are separated to another stream.

Fines: Small particles, such as dirt and organic residues, fall through the mesh for disposal or further processing.

Key Benefits:

- Efficient Sorting: Automatically separates mixed waste into specific streams.

- Improved Recycling: Enhances the purity of recyclables like paper and plastics.

- Cost Savings: Reduces the need for manual sorting and processing time.

- Versatility: Adapts to various waste streams, including municipal solid waste (MSW), industrial waste, and construction debris.

Applications:

- Recycling Plants: Sorting paper, plastics, and metals for recycling.

- Municipal Waste Sorting: Preparing waste for landfill, recycling, or energy recovery.

- Waste-to-Energy Plants: Removing non-combustible materials like glass and metal.

The ballistic separator is a vital part of waste sorting plants, enabling efficient resource recovery and contributing to sustainable waste management practices.

| BS04 | BS06 | BS08 | BS10 | BS12 | |

| Paddy Number | 4 | 4 - 6 | 6 - 8 | 6 - 8 | 6 - 10 |

| Paddle length | 5.5m | 5.5m | 5.5m | 5.5m | 5.5m |

| Angle adjustment | 0 – 25° | 0 – 25° | 0 – 25° | 0 – 25° | 0 – 25° |

| Sieve hole size | 20-80 mm | 30-80 mm | 30-80 mm | 30-80 mm | 30-80 mm |

| Fan Number | 2 - 4 | 2 - 4 | 2- 4 | 2 - 4 | 2 - 4 |

| Power | 5.5kw | 7.5kw | 11kw - 15kw | 11kw -18.5kw | 22kw |

| Throughput | 0-30 m³/h | 30-50 m³/h | 50-70 m³/h | 70-90 m³/h | 90-120 m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-18Spring Cone CrusherSpring cone crushers are generally used in the medium and fine crushing links of mine crushing, and are mainly used in the secondary crushing and tertiary crush...

-

2024-05-28Garbage screening drum screenTrommel screen is consisting of five parts: drum, frame, hopper, reducer and motor.After the material goes into the drum, it is screened along with the rotation...

-

2023-01-12Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...